Typically used for reseeding and overseeding pastures, the pneumatic Air 8 (8 outlets) and the Air 16 (16 outlets) are usually fitted to an OPICO Grass Harrow.

Designed to accurately meter and distribute grass and small seeds evenly across the full width of the grass harrow which opens up the soil, creating a tilth for improved seed to soil contact.

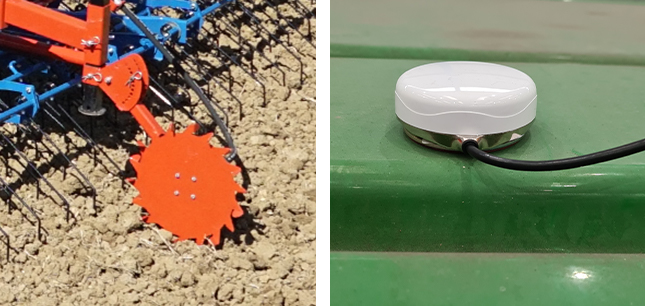

The seed roller metering is driven by a land wheel on the Air 8 and by an electronic GPS receiver on the Air 8E and Air 16E. The 8 outlet seeders have an electric fan whilst the 16 outlet has a hydraulic fan. Hydraulic fan upgrades are available for the Air 8 and 8E models.

The grass seeder seed rate can be varied from 1 to 80kg* per hectare, according to the type of seed being sown and whether reseeding or overseeding. Where oversowing only specific areas of a field, electronic seeders can also be switched on or off during the harrowing operation.

Sowing should always be followed with rolling to ensure good seed-to-soil contact is achieved.

The productivity of old or patchy leys can be rejuvenated and the life of the ley extended, simply by overseeding. This is especially useful where poor drainage or flooding has killed off grass in certain areas of a field, or where livestock have poached ground near gateways and troughs. In addition, the field does not have to come out of use.

With few effective clover-safe herbicides around, many farmers have adopted the approach of ridding the leys of perennial weeds like docks and thistles first, and only stitching-in clover once a clean grass ley has been established. Using the OPICO Grass Harrow, bare ground is exposed onto which the broadcast clover seed can land and establish.

Typically a first year reseed is expected to give 25% more yield than an old ley, although improvements of 40% have been known. Furthermore the modern grass varieties in seed mixtures have been bred to utilise nitrogen better, and have higher yields and digestibility than older grasses.

In soil conditions where it is difficult to establish new leys, aggressively cultivating the surface and heavily overseeding with a OPICO Seeder in consecutive seasons can give a reliable alternative.

After the usual ground cultivations, always roll the field at least once to obtain a good firm seedbed before harrowing and seeding and then roll again after to ensure good soil to seed contact.

BEST PRACTICE

For leys to reach their full potential for yield and quality, an integrated approach to grassland management is essential.

As well as harrowing, this includes: maintaining good drainage, avoiding soil compaction, reseeding with grass and clover mixtures appropriate to livestock and purpose, timely weed and pest control and tailoring fertiliser applications to compensate for soil nutrient shortfalls.

Grass is a very valuable crop and treating it as such can dramatically reduce seed costs.

FEATURES & BENEFITS

Precise Seed Metering

Unlike most other types of seeders, the OPICO Air 8, 8E and Air 16E grassland seeder uses individual metering rollers for each seed outlet enabling extremely accurate seed metering and guaranteeing the same amount of seed is fed to each outlet.

This is crucially important when using low seed rates and small seeds.

Four types of metering rollers are available. Two of these quickly interchangeable seed rollers are supplied as standard - the coarse (green) and fine (blue), the third or fourth can be purchased as an extra.

Forward speed related metering

Mechanical seeders come with spoked land wheel drive to give constant forward speed related metering. The electronic machine uses a GPS receiver.

On some tractors it is possible to connect to the tractors own GPS system. Forward speed related metering means accurately maintained application rates on high draft machines and in awkward shaped fields where ground speed may vary.

Pneumatic Seed Delivery

A hydraulic fan or two 12v electric fans provide the airflow to deliver the seed down the pipe to the correct position on the machine.

Electric fans have a full wiring looms and switch unit in the cab. There is an optional air flow alarm to warn the operator in case of blockage or malfunction.

Hydraulic drive units (left image) include a fan speed sensor and alarm to warn the operator if the fan is not turned on when seeding or if there is a malfunction.

RATE CONTROL

The amount of seed applied is controlled by the speed of the metering roller and is adjusted until the desired seed rate is achieved. The Air 8 mechanical drive seeder has a clever step-less gearbox to ensure reliability in work and seed rate.

The Air 8E and Air 16E (electronic) seeders have a speed sensing motor that is constantly checked and adjusted by the computer control box to give you a constant seed rate at all times.

A stepless gearbox and lever are used to adjust the seed rate.

Electronic Versions

The control box in the cab allows setting and adjustment on the move, and records the area that has been travelled and how much seed was put on that area.

Calibration

On all machines this is performed by removing the metering roller cover and using the calibration tray.

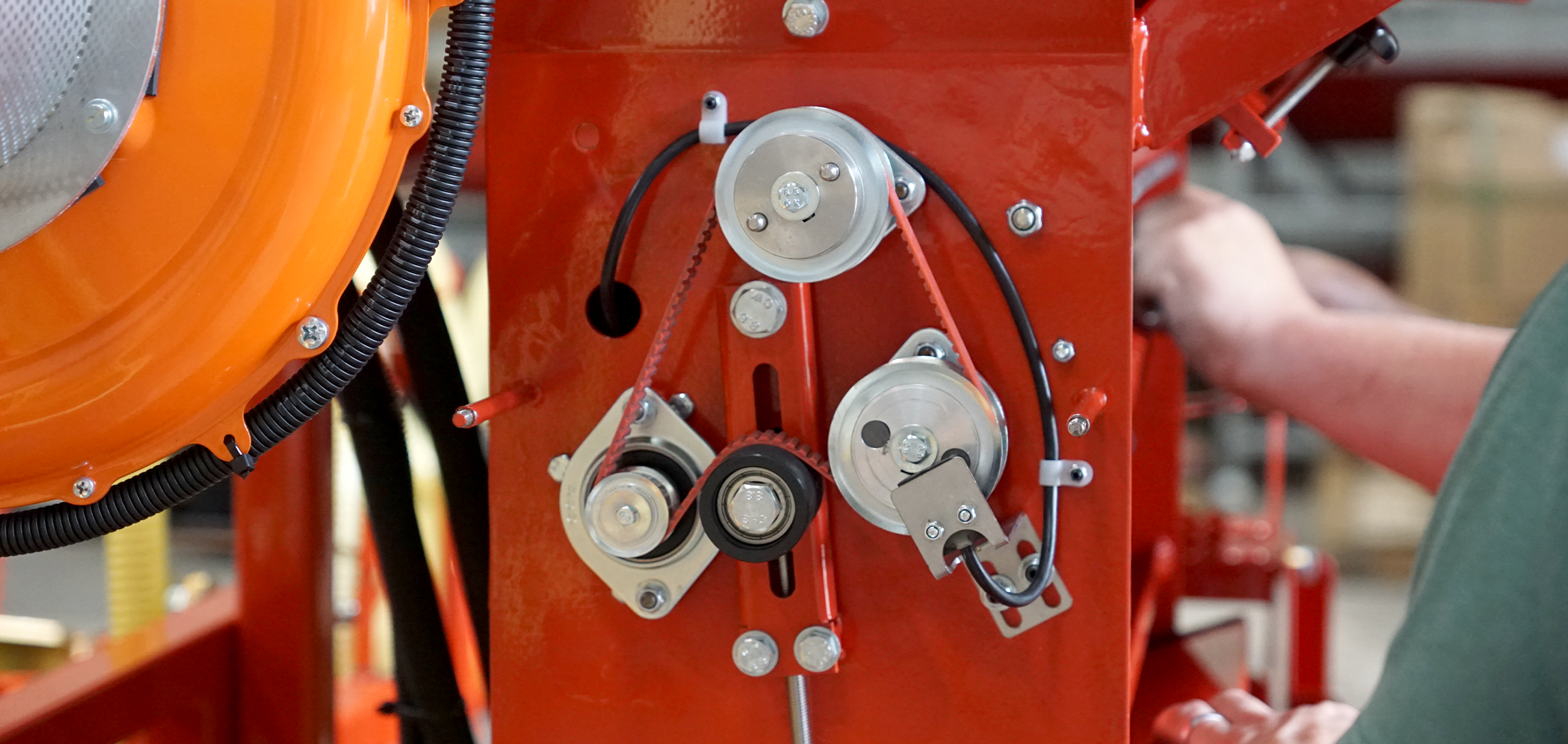

Drive Mechanism

Toothed, non slip drive belts are used to transmit power to the seed roller and agitator. Agitator disengagement for delicate seeds is done by simply reversing the agitator drive pulley.

AIR SEEDER MODELS

Share via WhatsApp

Share via WhatsApp