OPICO’s pneumatic electronic applicator is typically used for accurately applying microgranules (e.g. Avadex), and slug pellets.

The pneumatic Micro-Pro 8E (8 outlets) and Micro-Pro 16E (16 outlets) are usually fitted to a set of Cambridge rolls and drills. The metering roller is driven electronically utilising a GPS receiver for accurate forward speed monitoring on both models, with air supplied via a hydraulic fan.

- Micro-Pro 8E maximum spread width of 6m, hopper capacity 180 litres (400 litres optional)

-

Micro-Pro 16E maximum spread with of 12.3m, hopper capacity 400 litres

-

Individual metering roller per outlet – accurate application and spread pattern

-

Blue “fine” seed roller as standard – other rollers available

-

Adjustable outlets – balances airflow effect on pattern

-

Accurate Avadex application - independently tested

Each outlet is fed by an individual metering roller ensuring even distribution across the entire working width and guaranteeing the same amount is fed to each outlet - crucially important when using low rates and small granules to ensures a consistent, even application rate.

The amount of product applied is controlled electronically by a GPS receiver whereby the speed of the metering roller is constantly adjusted to match the forward speed, giving the application desired rate.

The Micro-Pro 8E and 16E machines have a load sensing drive motor that is constantly monitored and adjusted by the computer control box to give you a constant application rate at all times. It doesn’t matter if you slow down or increase your speed you will always get the desired application rate, so crucial with chemical application.

The 8 outlet machine spreads up to 6m, the 16 outlet machine up to 12m (up to 12.3m if fitted to a set of HE-VA rolls). Both machines are set at spacings of 75cm between outlets in order to deliver a robust double overlapping spread pattern and consequently even distribution across the entire working width.

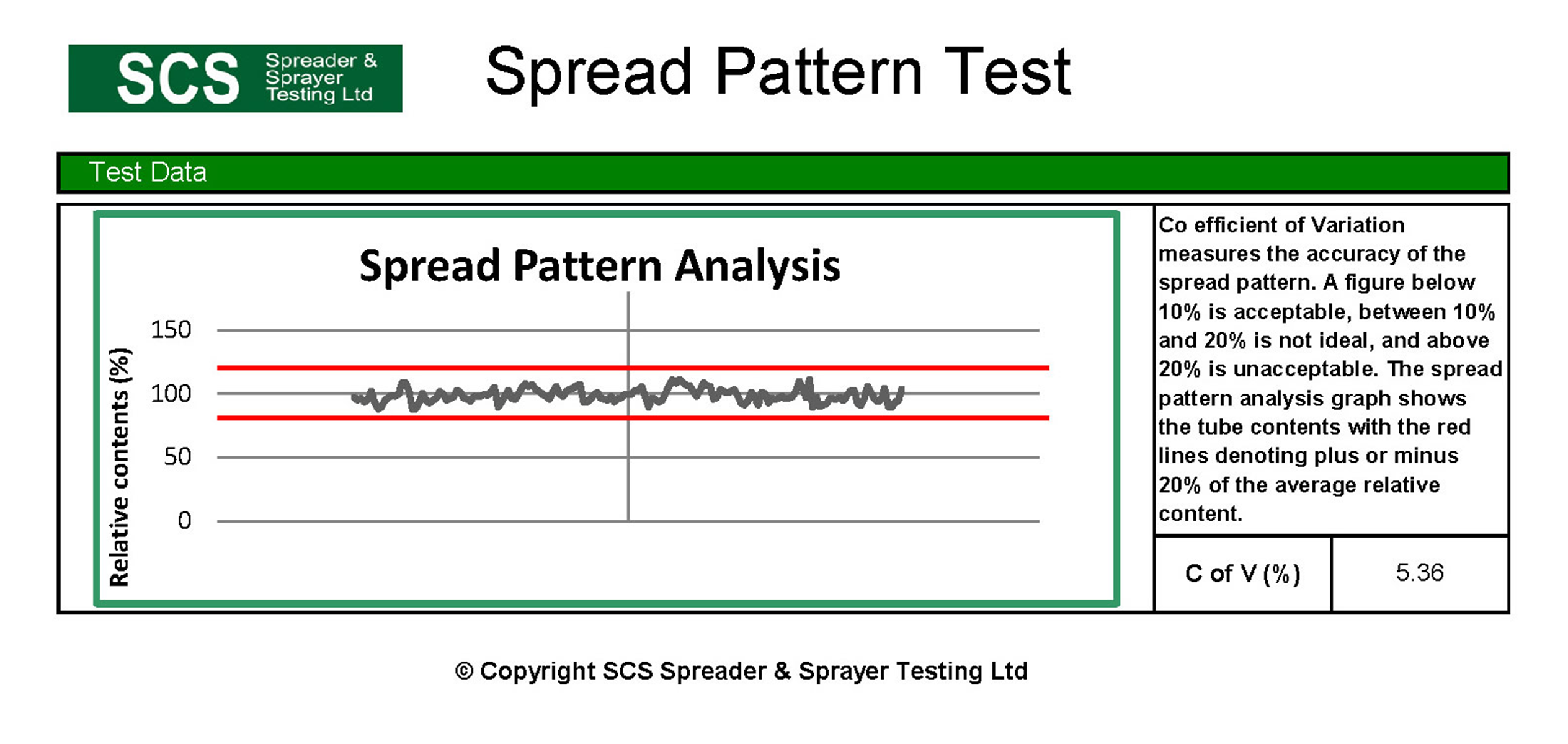

At OPICO we understand that an even spread pattern is as important as accurate metering, that’s why every machine is tested before it’s delivered to the customer. During testing the outlets are finely tuned to provide the best possible spread pattern. As a result, independent tests by SCS, measuring the complete application rate and spread pattern, showed that the Micro-Pro 16E spreading at 12m produces a marketing leading co-efficient of variation of under 5.5%.

INDEPENDENT TESTS

In independent tests measuring the complete spread pattern, the Micro-Pro 16E spreading at 12m has produced a market leading coefficient of variation of 5.36%.

A coefficient of variation (CV) is a measure of how evenly the product spreads. A CV value of up to 15% is acceptable, however if the CV increases to above 20%, this will result in crop and financial losses.

FEATURES & BENEFITS

Metering

The Micro-Pro comes as standard with the blue "fine" seed roller, however there are four different types of metering rollers available.

Unlike most other types of applicators, the OPICO Micro-Pro pneumatic electronic applicator uses individual metering wheels for each outlet enabling extremely accurate metering and guaranteeing the same amount is fed to each outlet.

This is crucially important when using low rates and small granules.

GPS Receiver Related Metering

All OPICO Micro-Pro's come as standard with a GPS receiver to give constant forward speed related seed metering. It doesn’t matter if you slow down or increase your speed, you will always get the correct seed rate.

Delivery

A hydraulic fan provides the airflow to deliver the granules down the pipe to the correct position on the machine.

Hydraulic drive units include a fan speed sensor and alarm to warn the operator if the fan is not turned on when seeding or if there is a malfunction.

Stainless Baffle

The stainless steel baffle guarantees even airflow within the metering system and ensures that only one outlet is fed from each metering segment.

RATE CONTROL

The amount of granules applied is controlled by the speed of the metering roller and is adjusted until the desired rate is achieved.

The Micro-Pro applicators have a speed sensing motor that is constantly checked and adjusted by the in-cab electronic control box to give you a constant seed rate at all times.

Electronic Versions

The in-cab control box allows setting and adjustment on the move, and records the area that has been travelled and how much product was put on that area.

Calibration

On all machines this is performed by removing the metering roller cover and using the calibration tray.

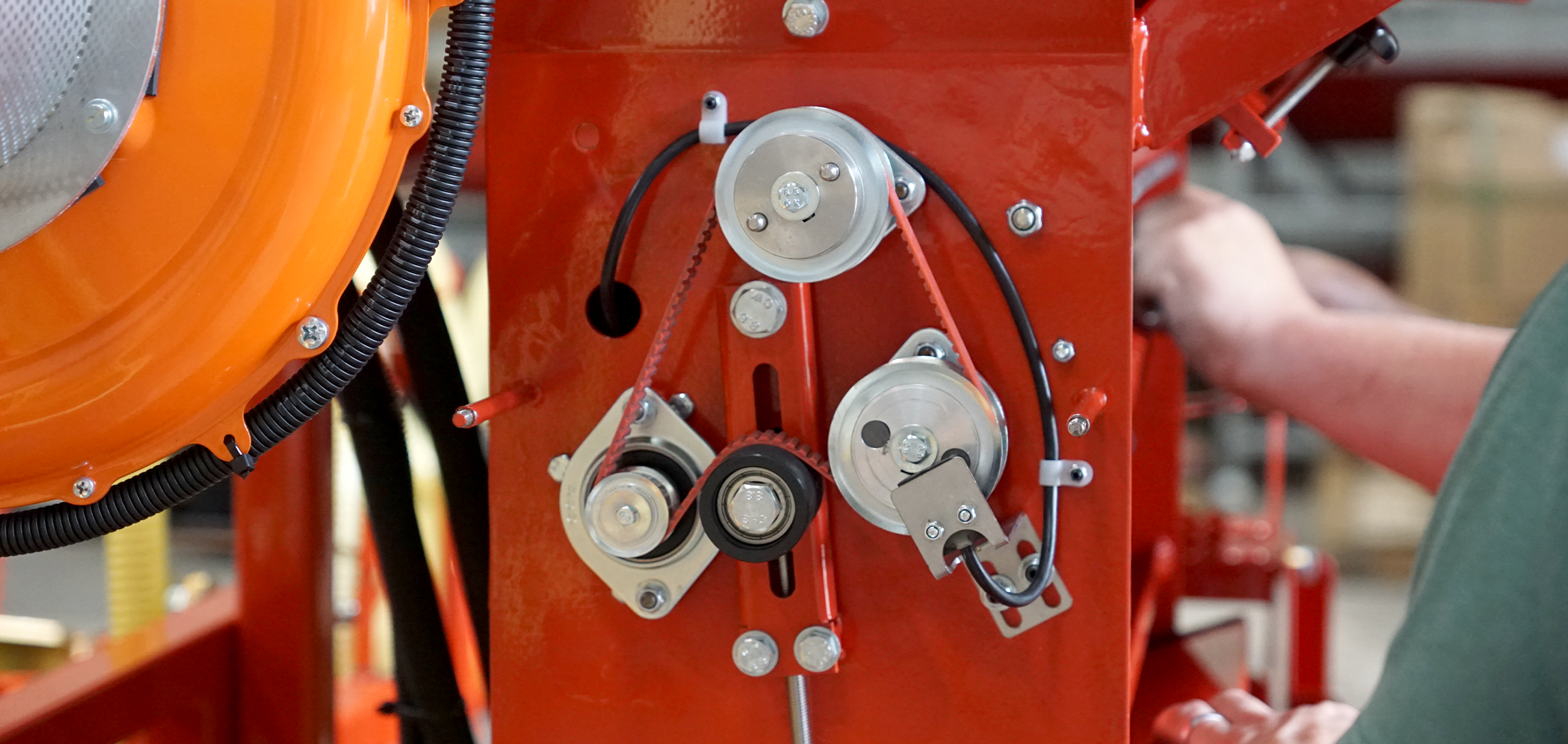

Drive Mechanism

Toothed, non slip drive belts are used to transmit power to the metering roller and agitator. Agitator disengagement for delicate material is done by simply reversing the agitator drive pulley.

MICRO-PRO MODELS

Share via WhatsApp

Share via WhatsApp