Many farms suffer from poor quality swards even if they plough and re-seed regularly. Furthermore, farms are using ever larger machinery on their grassland which brings with it an increasing problem of compaction.

The Sward Lifter is designed to alleviate compacted layers in the soil, opening up the subsoil to improve drainage and air interchange without significant damage to the productive sward. Waterlogged ground prevents grass growth and spring operations such as slurry and muck spreading, harrowing, fertilising and overseeding.

It also means livestock cannot be put out to graze which in turn effects forage requirements and productivity. The Sward Lifter, with its rugged construction, is specifically designed to break up hard pans and surface compaction while lifting and opening up the subsoil creating improved aeration and drainage.

BEFORE AND AFTER SWARD LIFTING

The untreated area photo (before) shows the top layer of the soil is water logged. The compacted layer is preventing the water from passing though.

In the treated photo (after) you can clearly see the water has been able to penetrate through the top layer and down through the soil profile.

Sward Lifting prevents water logging in the winter and allows oxygen into the grass root zone. As the grass is not put under water logging stress through the winter it is able to take advantage of warmer days and starts to grow earlier in the spring.

FEATURES & BENEFITS

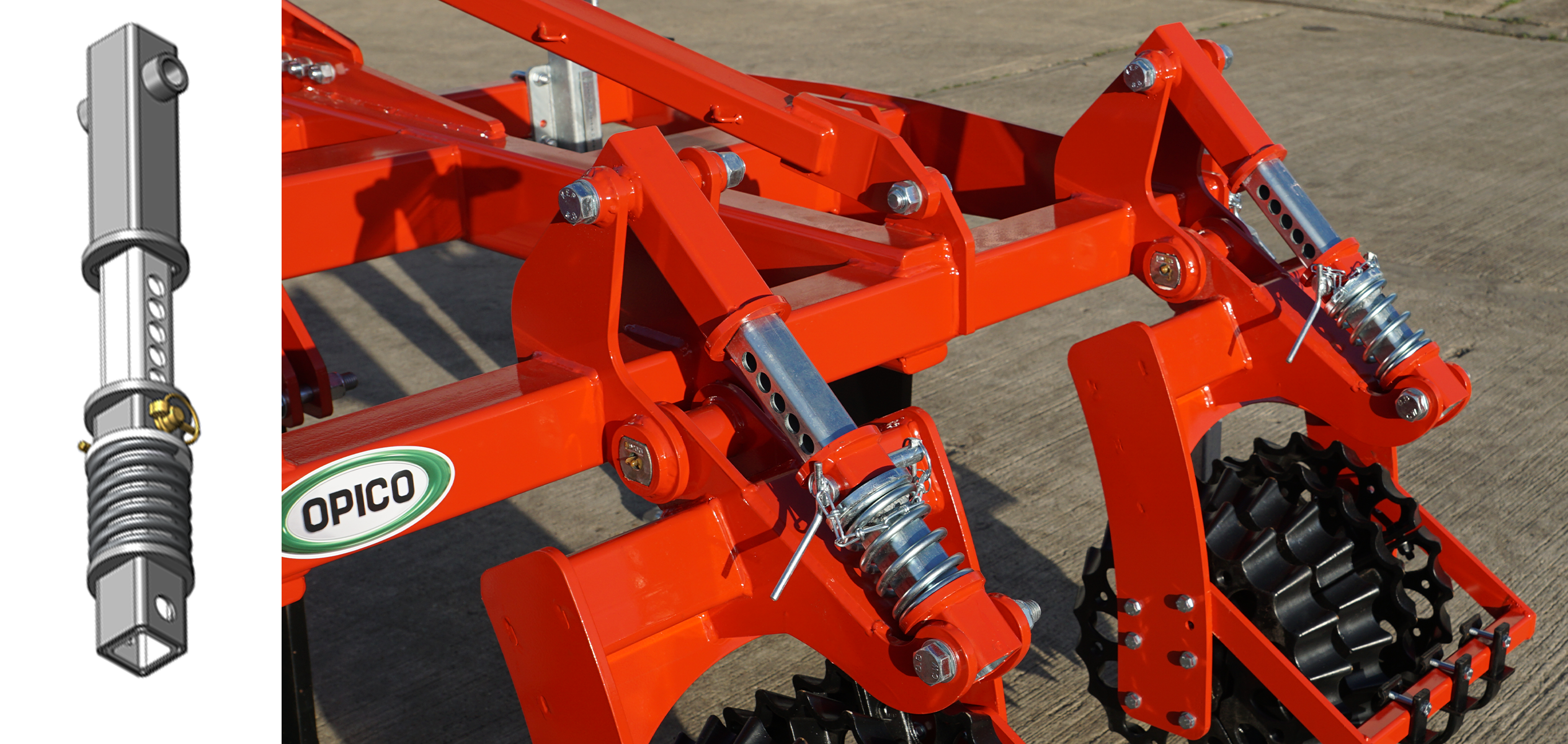

Shearbolt & Auto Reset

Leg protection is provided by either shearbolts or a hydraulic reset system to prevent damage from large obstacles under ground.

Legs & Points

The front of the leg has a replaceable, reversible shin.

Two cast steel point options consist of the 6cm standard and a 25cm winged point to suit all conditions and soil types.

Trailed Cutting Discs

The “opening” cutting disc is mounted on a spring-loaded trailing arm allowing it to trip out of the way of obstacles more easily. This cutting disc slices through the grass sward, preventing damage and soil burst on to the surface.

The cutting discs are bolted on to the frame allowing the operator to improve the alignment with the sward lifter leg. The bolted on trailed cutting disc can also be mounted in a high or low position to maintain maximum strength whatever the working depth, whilst the box section also allows space for a screw spindle depth adjuster which incorporates a depth marker scale for improved accuracy.

Simple Depth Adjustment

All machines come as standard with a pin adjustment system to control the depth of the leg and the pressure on the rear spring-loaded press roller.

The depth adjustment system controls both the depth of the leg and the pressure of the spring-loaded press roller. Each roller is individually spring loaded to close the slot and level the surface.

Press Rollers

Individual spring loaded depth rollers with a pin adjusted sliding depth sleeve follows each leg to close and level the surface leaving your field ready for use.

Bolt-on Headstock Connection

The three-point linkage frame allows for a bolt-on Cat lllL headstock connection (optional Cat ll bushes).

Anti-rotation design linkage pins are also included.

SWARD LIFTER MODELS

Share via WhatsApp

Share via WhatsApp