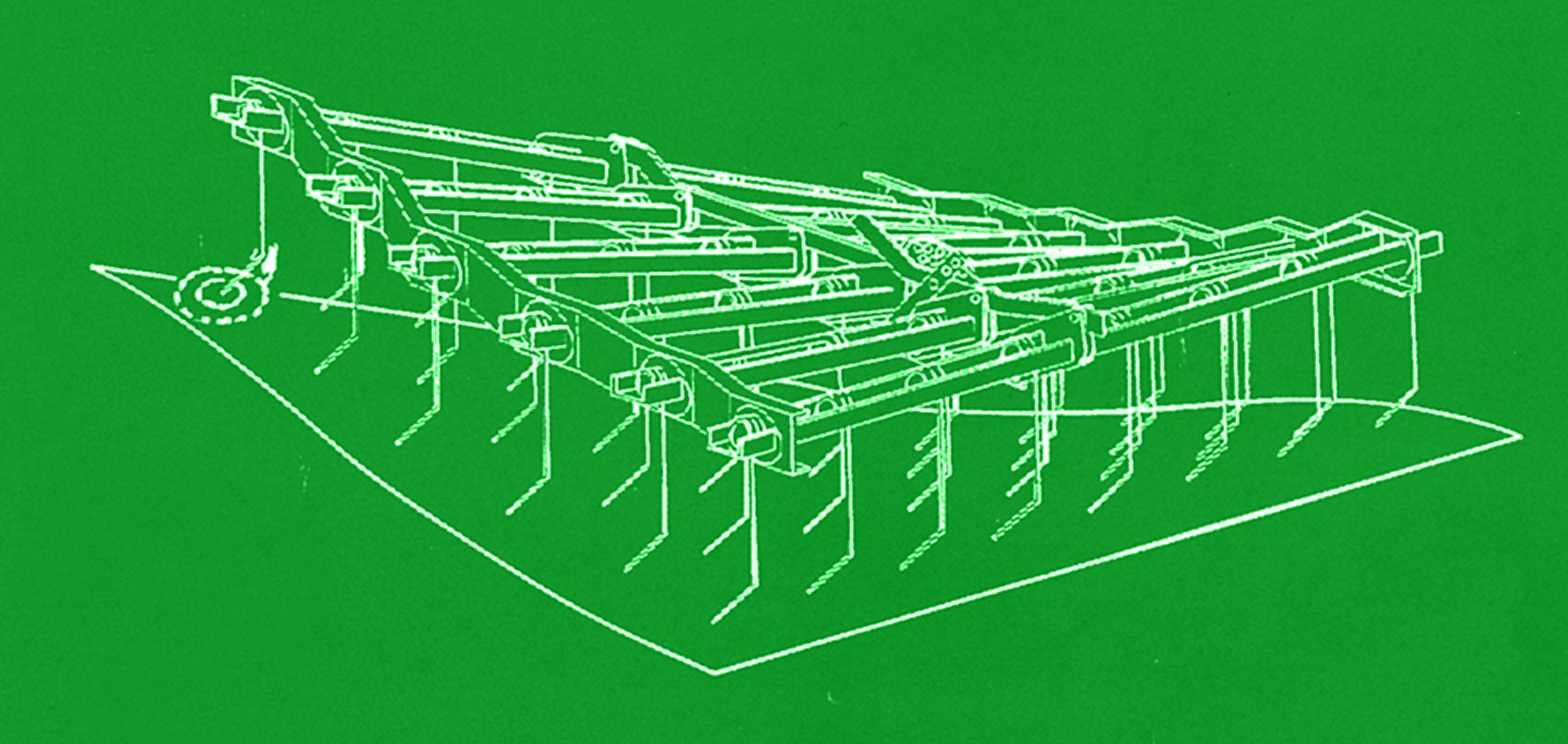

A high-output Grass Harrow and seeder, designed for large-scale farmers and contractors. The Grass Master consists of a heavy-duty harrow complete with levelling board, purpose-built to carry an Air 16E Pro Seeder.

The unit enables light cultivation and levelling to be carried out for complete re-seeds or over-seeding, with higher seed rates and faster working speeds than have been available up to now. The seeder has 16 outlets with hydraulic fan and 400-litre seed hopper. Other features are full in-cab electronic control plus variable seed rate on the move and radar.

FEATURES & BENEFITS

Ultimate contour following ability for uneven ground

- Even pressure is applied across every inch of the working width.

- The frame adapts to the ground contours with additional pressure being supplied from the accumulator to even the harrowing pressure across the working width.

- Active harrow bed suspension on the implement frame.

- A flexible harrow bed adapts to ground undulations.

Flexible bed

The flexible design of the tine beds allow them to follow the contours of the land ensuring effective coverage and even tine pressure. Each 1.5m bed has 48 tines spaced at 30mm centres apart and as well as ensuring good tine pressure onto the ground, this design allows it to self-clean as it moves through the sward.

Spring tines

The Grass Master's spring tines are able to penetrate even the hardest of ground, ripping out dead thatch and opening up the soil surface allowing air in to the root zone to stimulate and encourage growth. The oil hardened spring wire has three times the service life of a normal sprung steel wire. Channel mounting of tine coil prevents damage to the growing tip and leaf of the grass.

Adjustable tine angle

Quick and simple tine angle and pressure adjustment, ground conditions will determine how aggressive tine pressure needs to be for effective harrowing. On the OPICO Grass Master there are 10 tine angle settings so pressure can be altered, ensuring the vibrating action of the triple coil spring tine can be maximised.

Hydraulic Folding system

When in the transport position, the Grass Master folds up to 2.8m. This allows easy transportation on the road and through narrow gateways.

Hydraulic cylinder with accumulator and hydraulic shut-off valve can be locked for safe road transport.

Pneumatic Seed Delivery

A hydraulic fan provides the airflow to deliver the seed down the pipe to the correct position on the machine.

Hydraulic drive units include a fan speed sensor and alarm to warn the operator if the fan is not turned on when seeding or if there is a malfunction.

Precise Seed Metering

Unlike most other types of seeders, the OPICO Air 16E Pro seeder uses individual metering seed rollers for each seed outlet enabling extremely accurate seed metering and guaranteeing the same amount of seed is fed to each outlet.

This is crucially important when using low seed rates and small seeds

Four types of metering rollers are available. Two of these quickly interchangeable seed rollers are supplied as standard - a coarse (green) seed roller and a fine (blue) seed roller. The third or fourth can be purchased as an extra.

Forward speed related metering

All OPICO Grass Master's come as standard with radar to give constant forward speed related seed metering. It doesn’t matter if you slow down or increase your speed you will always get the correct seed rate.

RATE CONTROL

The amount of seed applied is controlled by the speed of the metering roller and is adjusted until the desired seed rate is achieved.

The Air 16E Pro seeder has a speed sensing motor that is constantly checked and adjusted by the computer control box to give you a constant seed rate at all times

Control Box

The control box in the cab allows setting and adjustment on the move, and records the area that has been travelled and how much seed was put on that area.

Calibration

On all machines this is performed by removing the metering roller cover and using the calibration tray.

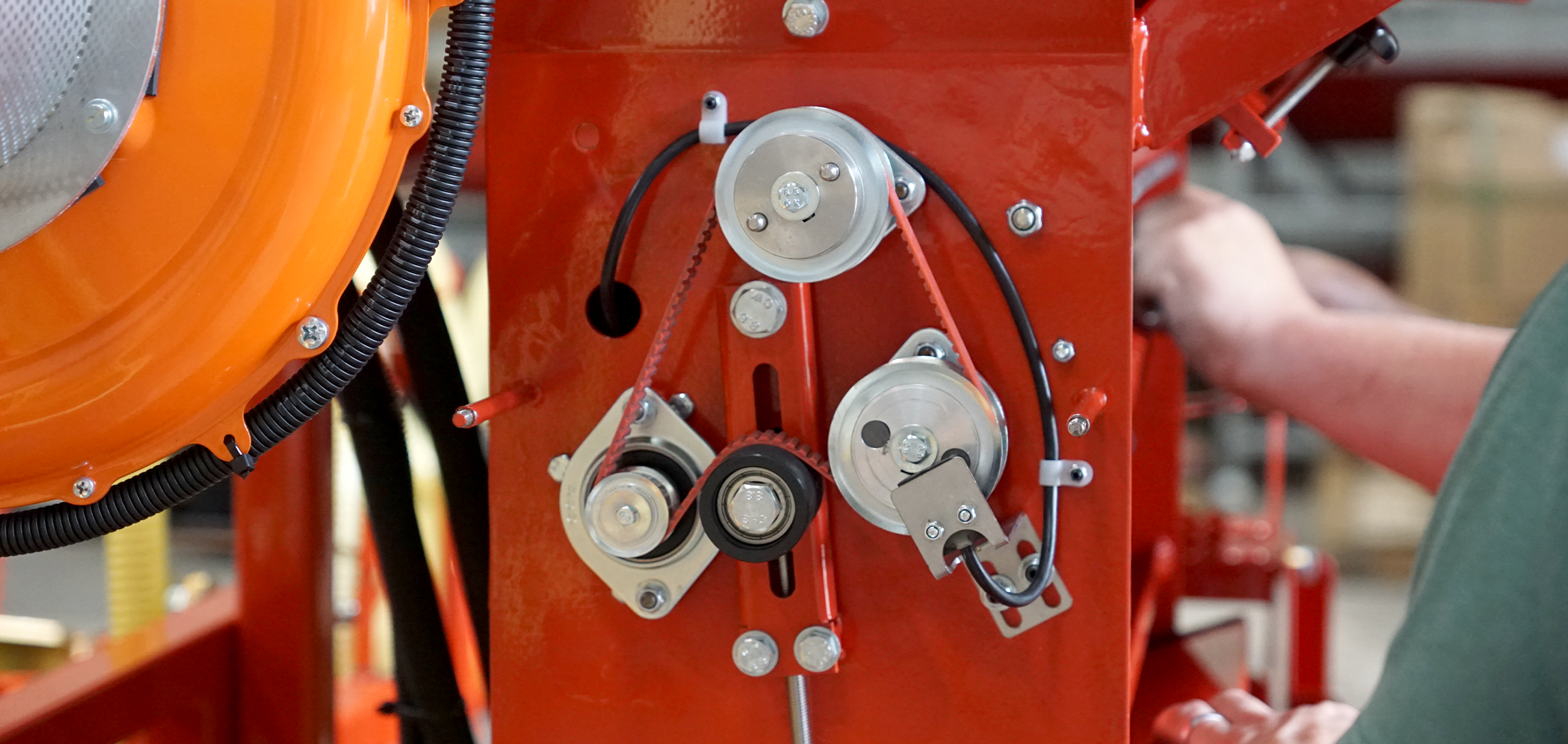

Drive Mechanism

Toothed, non slip drive belts are used to transmit power to the seed roller and agitator. Agitator disengagement for delicate seeds is done by simply reversing the agitator drive pulley.

GRASS MASTER MODELS

Share via WhatsApp

Share via WhatsApp