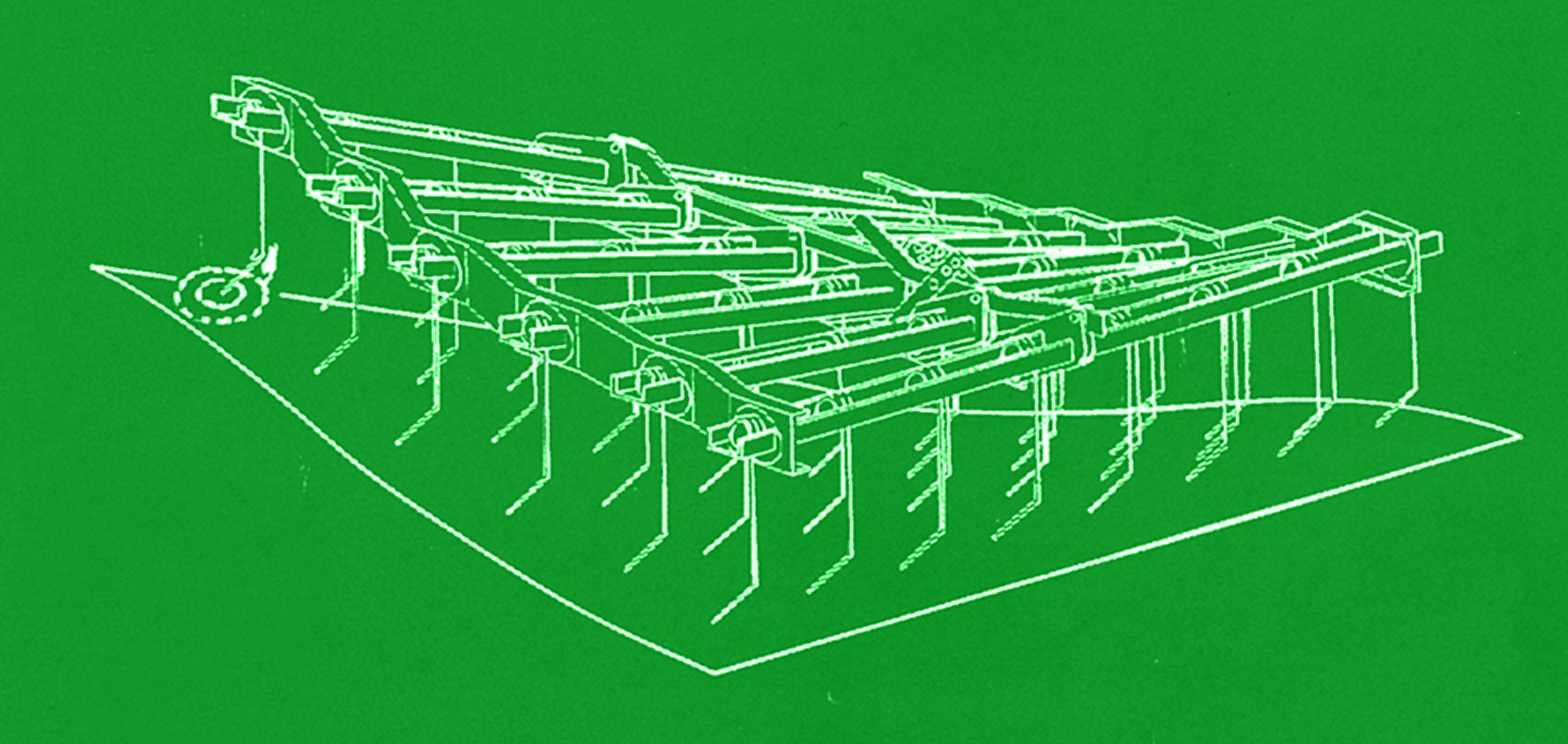

The OPICO grass harrowing concept simply transforms the way you work your grass. The angle of the tine combined with the overall design of the harrow makes it ideal for stimulating new grass or renovating old pastures.

With an OPICO Grass Harrow, leys can be re-vitalised and dry matter yields boosted. You can attach an OPICO Air Seeder, and oversow old worn leys to boost grass and clover content, or start afresh and put down a brand new ley with the harrow and seeder combination.

The OPICO Grass Harrow covers every inch of the ground, thanks to its unique contour flexing tine bed. It clears moss, opens the surface, improves aeration and encourages growth. Like all good ideas it is very simple and is now recommended by thousands of farmers who have switched to this common-sense approach to what used to be a ‘harrowing’ job.

FEATURES & BENEFITS

The OPICO Grass Harrow has revolutionised grass harrowing in recent years, with larger working widths, more adjustment and aggressive spring tines mean that a better job can be achieved faster and at a lower cost.

With typical working speeds of 4.5mph to 7mph the Grass Harrow is a high capacity machine, a 6m for example, is more than capable of covering over 100 acres in a normal working day. The working widths range from a very handy 1.5m up to the very wide 27m. There are rigid, mechanical and hydraulic folding units with a choice of 7mm or 8mm tines.

The machines are designed for strength without the need for high horsepower and are equipped with a fully adjustable depth wheel, which works alongside the tine angle settings for maximum effectiveness. The hydraulic folding models have a single acting ram with an accumulator that applies 8-10 bar pressure over the full width of the harrow to give true contour following across the field.

Ultimate contour following ability for uneven ground

- Even pressure is applied across every inch of the working width.

- The frame adapts to the ground contours with additional pressure being supplied from the accumulator to even the harrowing pressure across the working width.

- Active harrow bed suspension on the implement frame.

- A flexible harrow bed adapts to ground undulations.

Flexible bed

The flexible design of the tine beds allow them to follow the contours of the land ensuring effective coverage and even tine pressure. Each 1.5m bed has 48 tines spaced at 30mm centres apart and as well as ensuring good tine pressure onto the ground, this design allows it to self-clean as it moves through the sward.

Spring tines

The Grass Harrow's spring tines are able to penetrate even the hardest of ground, ripping out dead thatch and opening up the soil surface allowing air in to the root zone to stimulate and encourage growth. The oil hardened spring wire has three times the service life of a normal sprung steel wire. Channel mounting of tine coil prevents damage to the growing tip and leaf of the grass.

Adjustable tine angle

Quick and simple tine angle and pressure adjustment, ground conditions will determine how aggressive tine pressure needs to be for effective harrowing. On the OPICO Grass Harrow there are 10 tine angle settings so pressure can be altered, ensuring the vibrating action of the triple coil spring tine can be maximised.

Construction

The construction of the headstock consists of interlocking pieces of steel so the Grass Harrow doesn’t just rely on the welding for strength. The frames and beds are powder-coated and most of the other steel parts are anodised so your harrow will stay in good working order and looking newer for longer.

Hydraulic cylinder with accumulator and hydraulic shut-off valve can be locked for safe road transport.

Folding system

When in transport position, the hydraulic folding models fold up between 2.5m and 3m dependant on the model of grass harrow. This allows easy transportation on the road and through narrow gateways.

7mm or 8mm Tines, that is the question?

Many farmers automatically believe that the 8mm tine will do a better job because it is stronger. That's not necessarily the case! The key to making the best job with your harrow is getting the tines to do the work.

A spring tine is designed to "spring" causing the point to oscillate from side to side. On a Grass Harrow this makes sure all the ground is covered by the tines and achieves the maximum effect from one pass.

In many cases the 8mm tine can be too rigid and simply drag through the sward in a straight line with no "spring" effect. As a general rule of thumb choose the 7mm tine when you are predominantly working on temporary grassland (leys under 5 years) which is being regularly cut for silage, grazed and managed.

Choose an 8mm tine when you are using the harrow on old permanent pastures and rough grazing in the main.

GRASS HARROW MODELS

Share via WhatsApp

Share via WhatsApp