Easy to install and relocate when necessary, OPICO Grain Dryers do not require vast expenditure on handling equipment and can easily dry up to 480 tons per day automatically, with minimal supervision.

Fuelled using diesel or gas, and with 3 phase or PTO drive, OPICO dryers recirculate the grain constantly to dry thoroughly and consistently whilst improving hectolitre weights and augmenting quality.

DON'T GET CAUGHT OUT BY ANOTHER WET HARVEST...

OPICO'S GRAIN DRYERS HAVE THE SOLUTION

Many farms could increase drying output at minimal additional cost by simply arranging their system better. Electric drive and fully automated dryers are another good way of increasing drying output per day without increasing the size of the dryer being used.

Whether you choose a manual or an automatic system the ease of management and peace of mind are key benefits of owning an OPICO dryer. For an introduction to our range of OPICO Diesel and Gas Grain Dryers, why not watch our informative product walk around video, below.

10 GOOD REASONS TO USE RECIRCULATING BATCH GRAIN DRYERS

- Recirculating - Constant mixing for even drying.

- Augers - Polishes the grain, improving sample.

- Grain Cleaner - Removes weed seeds and broken grains

improving hectolitre weight. - Grain is Constantly Moving - Airflow through crop is better

decreasing drying time. - Wet or Dry Capabilities - Can handle and dry the very wettest of grain.

- Forced Drying and Cooling - You are in control: grain is ready to sell when you want.

- Self-contained - Minimal additional handling equipment

required. - Quiet - To reduce noise in sensitive areas.

- Resale Value - Being mobile, OPICO Dryers retain a high resale value.

- Flexibility - Can be adapted to fit into most drying systems.

WHY CHOOSE AN OPICO DRYER?

Minimise non-drying time

Loading time and unloading time is dead time when using a dryer. OPICO dryers have high-capacity loading augers, recirculating augers and unloading augers, reducing non-drying time and increasing throughput.

Air flow through the grain

The more air you can blow through grain the quicker the grain will dry and cool. OPICO dryers have high-capacity fans in relation to the size of the dryer which speeds up drying and cooling, decreasing batch time and increasing throughput.

Heating the grain

Larger burners attain the drying temperatures quicker and maintain a more consistent drying temperature, decreasing drying time and increasing throughput.

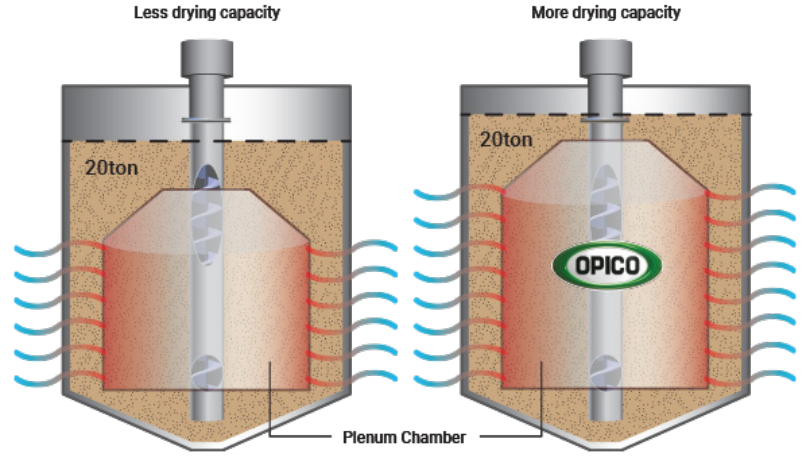

Size of the drying zone

The size of the plenum chamber in a grain dryer dictates the amount of grain that is being dried at any one time. The holding capacity of a grain dryer is irrelevant to the drying capacity, the larger the plenum area, the higher drying capacity. (See image).

Share via WhatsApp

Share via WhatsApp