Why get caught out by another wet harvest when OPICO's Grain Dryers have the solution.

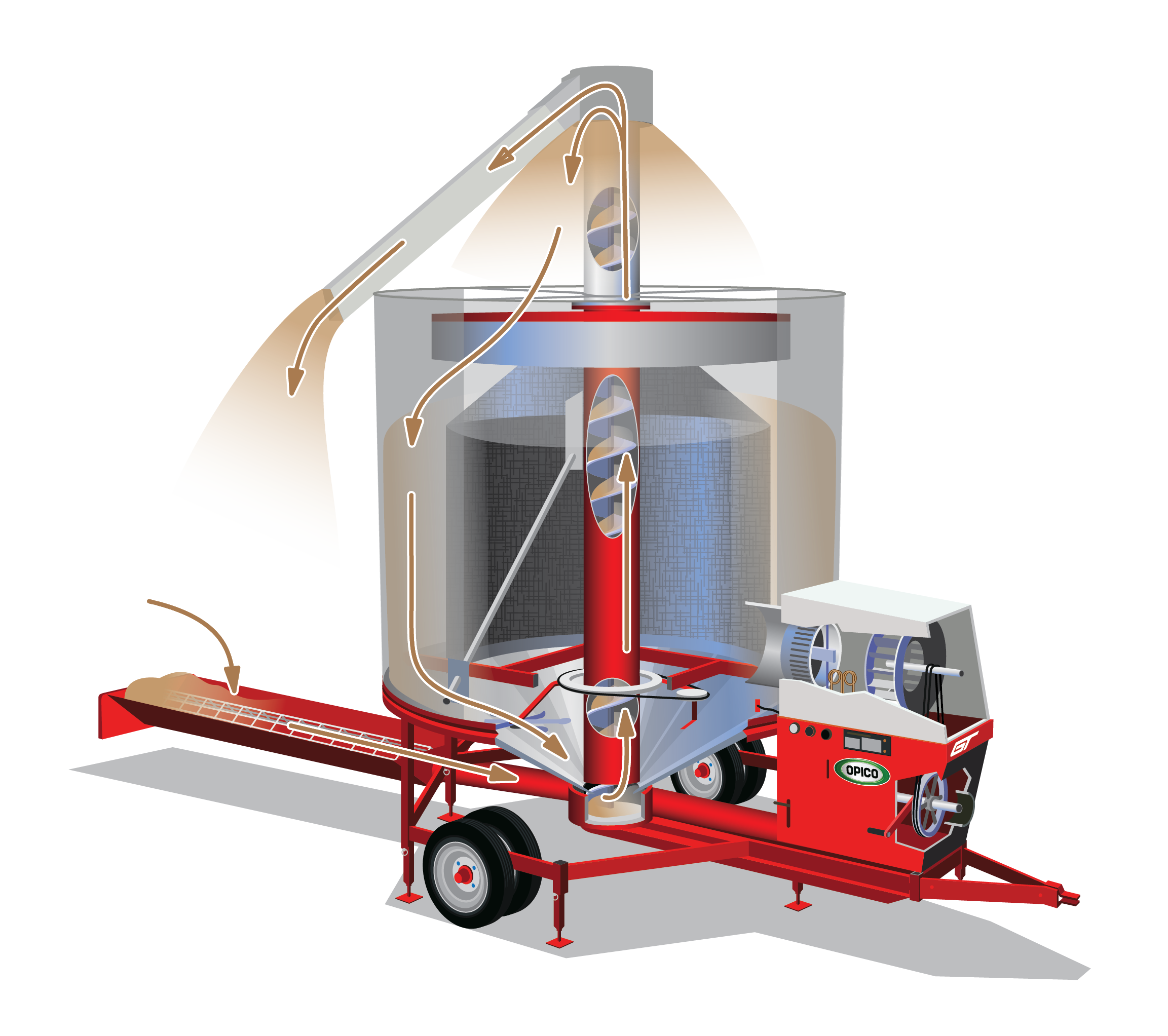

Easy to install and relocate when necessary, OPICO Grain Dryers do not require vast expenditure on handling equipment and our Gas Grain Dryers can easily dry up to 168 tons per day automatically, with minimal supervision. Using gas with 3 phase or PTO drive OPICO dryers recirculate the grain constantly to dry thoroughly and consistently whilst improving hectolitre weights and augmenting quality.

WHY CHOOSE OPICO DRYERS?

10 Good Reasons to use an OPICO Grain Dryer

- Recirculating - Constant mixing for even drying.

- Augers - Polishes the grain, improving sample.

- Grain Cleaner - Removes weed seeds and broken grains improving hectolitre weight.

- Grain is Constantly Moving - Airflow through crop is better decreasing drying time.

- Wet or Dry - Can handle and dry the very wettest of grain.

- Forced Drying and Cooling - YOU'RE in control, grain is ready to sell when YOU want.

- Self Contained - Minimal additional handling equipment required.

- Quiet - To reduce noise in sensitive areas.

- Resale Value - Being mobile OPICO Dryers retain a high resale value.

- Flexibility - Can be adapted to fit into most drying systems.

FEATURES & BENEFITS

Minimise non drying time

Loading time and unloading time is dead time when using a dryer. OPICO dryers have high-capacity loading augers, recirculating augers and unloading augers, reducing non-drying time and increasing throughput.

Air flow through the grain

The more air you can blow through grain the quicker the grain will dry and cool. OPICO dryers have high-capacity fans in relation to the size of the dryer which speeds up drying and cooling, decreasing batch time and increasing throughput.

Heating the grain

Larger burners attain the drying temperatures quicker and maintain a more consistent drying temperature, decreasing drying time and increasing throughput.

Size of the drying zone

The size of the plenum chamber in a grain dryer dictates the amount of grain that is being dried at any one time. The holding capacity of a grain dryer is irrelevant to the drying capacity, the larger the plenum area, the higher drying capacity.

GT Dryers use Liquid Propane Gas fuel for drying heat. A tank or a group of bottles are needed to supply the dryer with liquid gas which is vaporised within the dryer and supplied to the burner ring.

This provides a very clean, easily controllable and even heat which is cost effective and means that the burner requires minimal operator input and minimal servicing. When drying malting barley and milling crops many owners prefer Gas as a fuel for its guaranteed cleanliness and efficiency.

Some of the major benefits you can expect from an OPICO GT portable batch dryer:

- Easy installation

- Minimal management required

- Run on clean LP gas

- Require minimal service

- Full range of models available

- Improved presentation of grain through the polishing effect of the recirculation

- Central auger constantly recirculates grain for even drying

- Inner chamber has large perforations to maximise airflow whilst the outer sheet has small perforations to prevent small seed loss

- Improved hectolitre weight through cleaning action of the built in grain cleaner

- Loading hopper allows grain to be loaded at ground level, discharge from the top

- Grain is dried consistently throughout the batch

- Grain sampler

- Cone shaped silo base takes grain to the bottom of the main auger

- Agitator ensures constant flow of grain

- Maintain high resale values

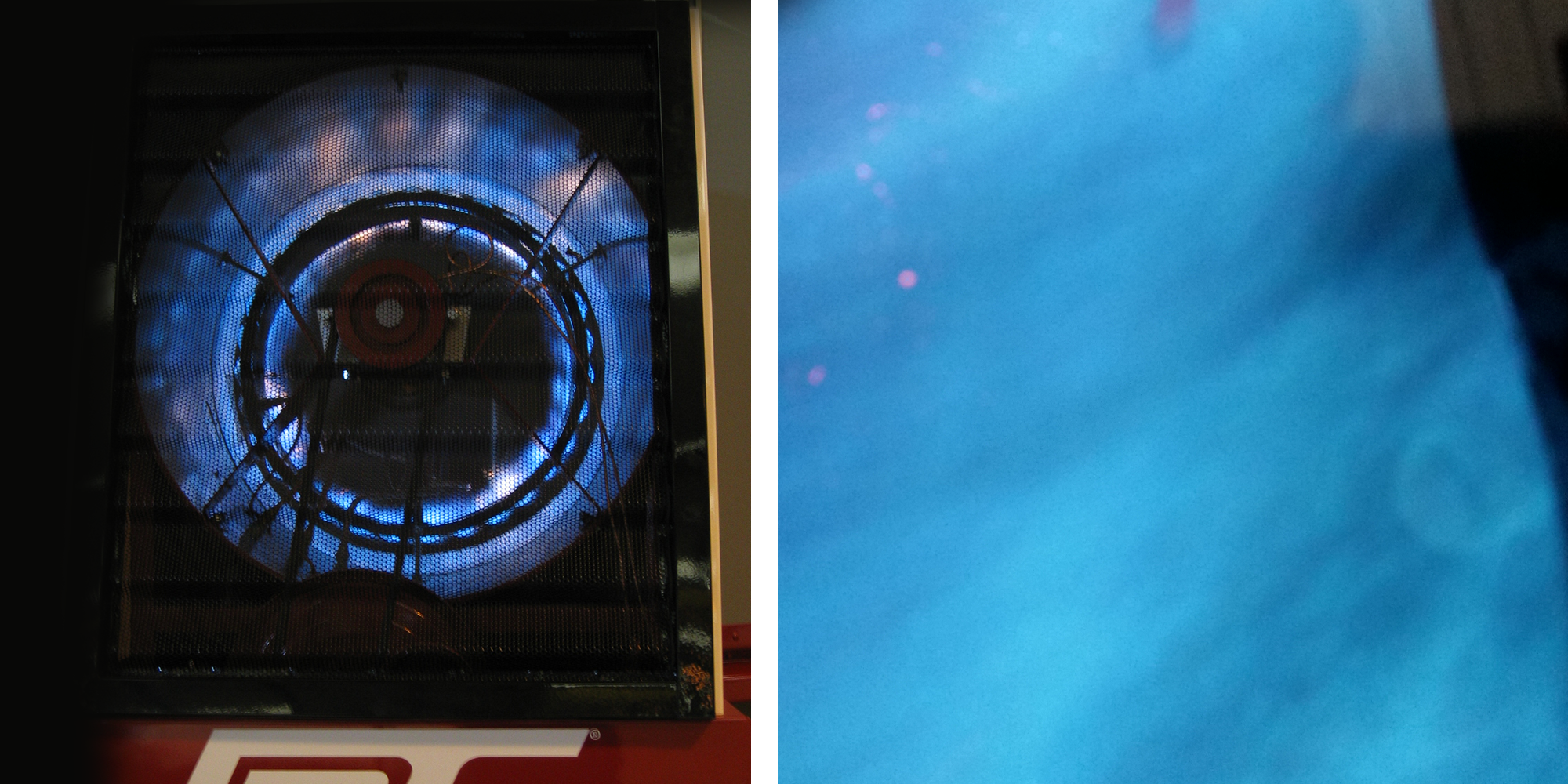

Liquid Gas Vaporiser and Ring Burner

Efficient Clean Drying

The gas is piped into the burner unit in liquid form and passes through a vaporising ring before being burnt in a ring burner, as liquid gas expands 100 times to become vapour this ensures high temperatures can be attained easily. As gas burns very cleanly, apart from long term servicing, little input is required by the operator.

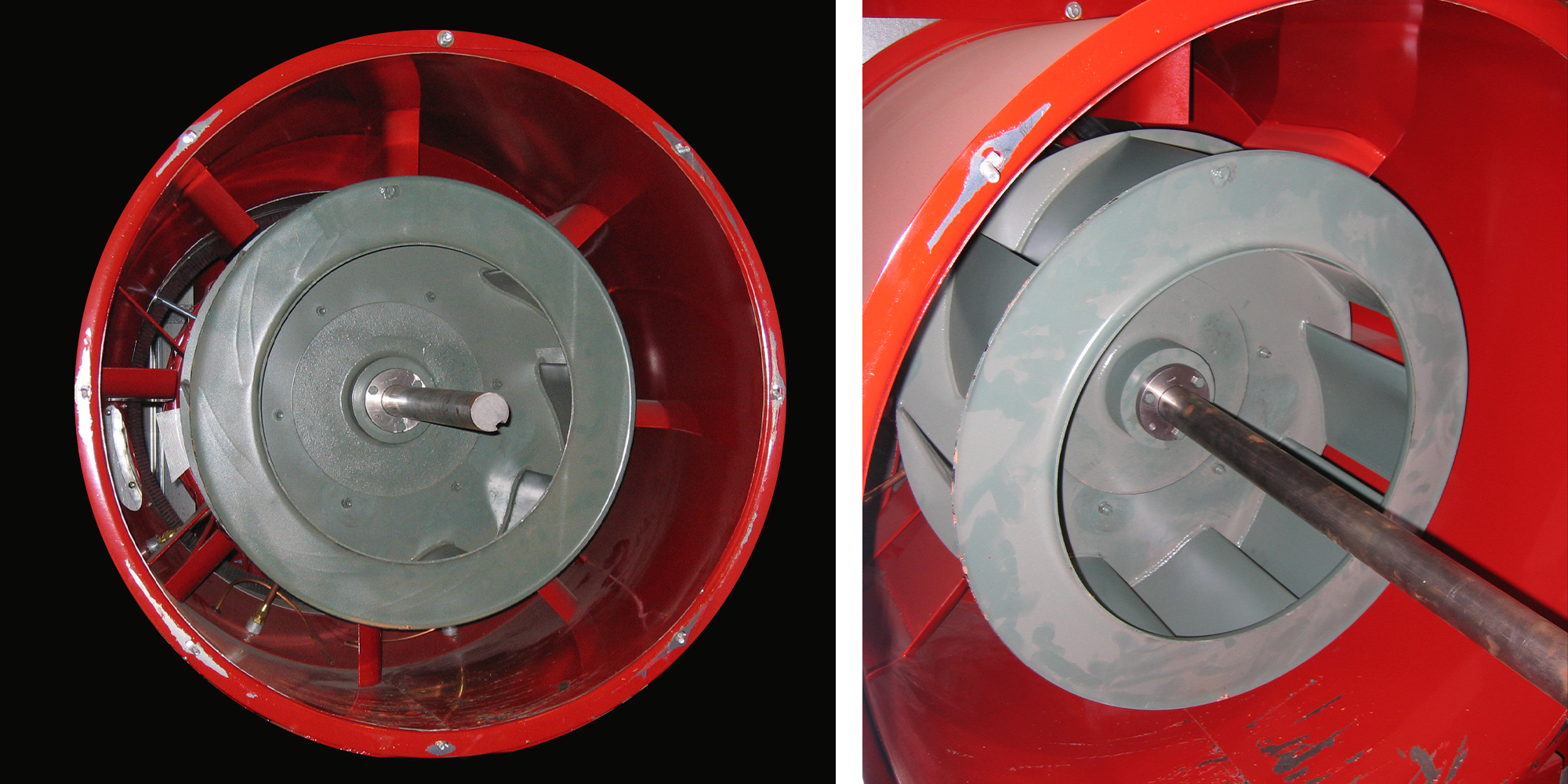

Custom Built Centrifugal Fan

Quiet for Sensitive Areas (QF Models ONLY)

QF Models use a large custom built centrifugal fan to create the airflow required to dry with, as the fan blades do not cut through the air aggressively this produces less noise resulting in a decibel rating of 74 and the ability to work 24 hours a day in noise sensitive areas.

CONTROLS

Push Button Controls

Simple Operation (355XL, 555XL, 575QF Models ONLY)

The base models have simple push button and turn dial controls to allow the operator to quickly and easily set the dryer up for work, they also incorporate fail safes to prevent problems in the event of any mechanical failure.

Grain Guard Controller

Operator Guidance and Self Diagnostics (395QF, 595QF, 600QF, 795QF, 800QF, RAB 8000 Automatic Models ONLY)

Models with the Grain Guard fitted benefit from a menu system which guides the operator through setting his dryer up for a particular mode of operation and for specific crops with example temperatures pre-set into the controller. The Grain Guard also has a diagnostic function which controls the fail safes and will highlight the problem if there is one.

The Grain guard Control Box can automatically monitor the drying temperature, grain temperature, flame failure, power failure, fan failure, fuel supply, agitator, auger and PTO speeds. During the entire time the dryer is in operation the electrical supply is monitored.

Should any of the functions of the dryer fail the gas supply is automatically shut off, a precise message is given on a LCD read out. The safety and fault diagnosis is carried out automatically. Maintenance and servicing is made more effective and almost immediate diagnosis of any fault can be made by the operator thus requiring minimal service intervention.

GRAIN DRYER MODELS

Share via WhatsApp

Share via WhatsApp